1. Description

Bailu cartridge heater for injection mold is a heating element specifically designed for use in injection molding machines. It is created to provide precise and efficient heating for the molding process.

Cartridge heater is inserted into the mold cavity, where it directly heats the material and maintains the required temperature for molding. The precise temperature control and even distribution of heat provided by the cartridge heater are crucial for achieving consistent and high-quality molded products.

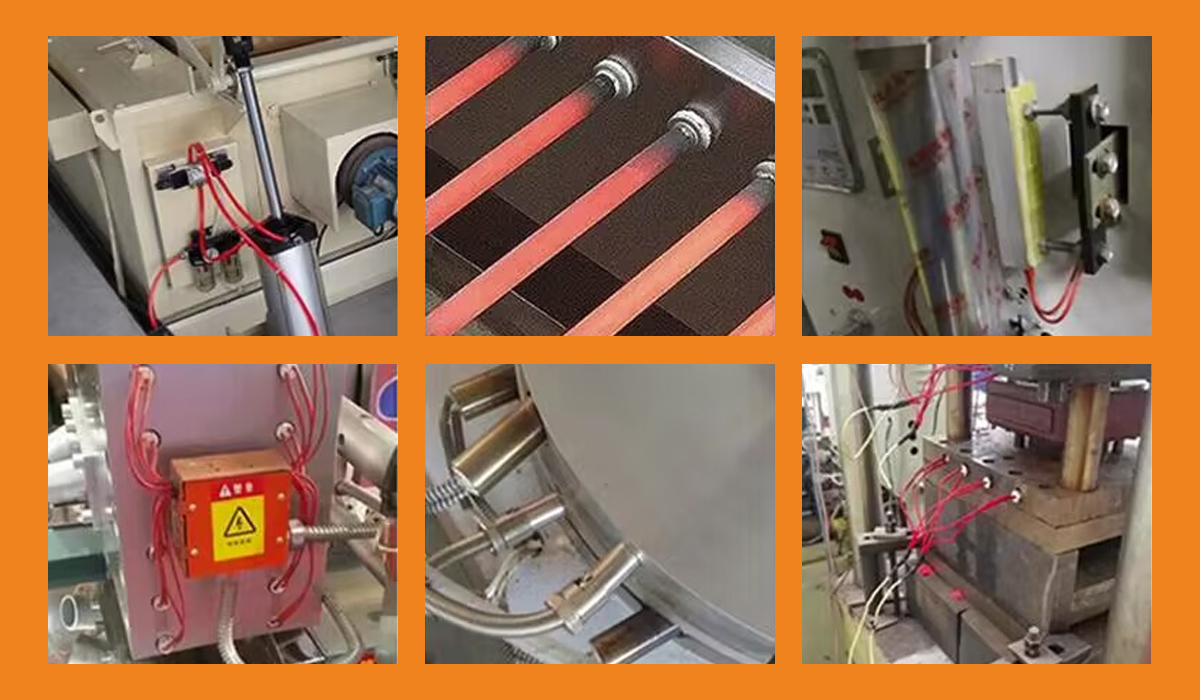

2. Product Pictures

3. Application

4. Key Attributes

|

Type |

Cartridge Heater |

|

Voltage |

12V-480V/Customized |

|

Place of Origin |

China |

|

Warranty |

1 Year |

|

Key Selling Points |

High-accuracy |

|

Dimension(L*W*H) |

Customized |

|

Working Temperature Range |

0 - 850 ℃ |

|

Standard leads length |

300mm |

|

Insulation (when cold) |

5 Min Ohmios 500 Watts minimun |

|

Heat intensity |

Normally Not exceeding 30W/cm²,but also has special wattage |

|

Cold areas |

Depends on length and diameter |

|

Resistance tolerance |

±5% |

|

Sheath material |

Seamless SS304 / SS316/SS321 / Incoloy800 |

|

Tube diameter |

2-50mm |

|

Outgoing method |

Inner/outter lead wire |

|

Lead material |

Pure nickel wire/Silicone fiberglass wire/ silicone wire/Teflon wire |

5. Precautions For Use

(1) Electrical Safety: Ensure that the electrical supply is properly grounded, and all electrical connections are secure. Follow electrical safety guidelines and regulations to prevent the risk of electrical shock or fire hazard.

(2) Proper Installation: Install the cartridge heater correctly, following the manufacturer’s instructions. Make sure it is tightly secured in the mold cavity to prevent movement or dislodging during operation.

(3) Temperature Control: Use a reliable temperature control device, such as a thermostat or temperature controller, to maintain the desired operating temperature. Avoid exceeding the recommended temperature range to prevent overheating and potential damage to the cartridge heater or the injection mold.

(4) Regular Maintenance: Inspect the cartridge heater regularly for signs of wear, damage, or corrosion. Replace any damaged or worn-out parts promptly to prevent performance issues or safety risks.

(5) Avoid Overloading: Do not exceed the maximum voltage or wattage rating specified by the manufacturer. Overloading the cartridge heater can lead to overheating, shortened lifespan, or even failure.

(6) Proper Ventilation: Ensure that the injection molding machine and surrounding area are well-ventilated to dissipate excess heat generated by the cartridge heater. Proper ventilation helps maintain stable operating conditions and extends the lifespan of the heater.

(7) Operator Training: Provide proper training to machine operators on the usage, handling, and maintenance of the cartridge heater. Educate them about safety precautions and procedures to minimize the risk of accidents or damages.

(8) Shutdown Procedures: Follow proper shutdown procedures when not in use or during maintenance activities. Allow the cartridge heater to cool down completely before handling or performing any maintenance tasks.

6. Why Choose Bailu Electric Heating Element?

(1) Quality and Reliability:We use top-grade materials and adhere to strict quality control processes to ensure that our products meet or exceed industry standards.

(2) Customization Options: Whether you need specific dimensions, wattage, voltage, or other specifications, our team can work with you to develop a tailor-made solution that perfectly suits your requirements.

(3) Expertise and Experience:Our team of skilled engineers and technicians are knowledgeable in the latest heating technologies and can provide expert guidance and support throughout your project.

(4) Exceptional Customer Service:Our team of skilled engineers and technicians are knowledgeable in the latest heating technologies and can provide expert guidance and support throughout your project.

(5) Competitive Pricing: Bailu Electric Heating Element strives to offer competitive pricing without compromising on quality. We work efficiently, optimize our manufacturing processes, and maintain excellent supplier relationships to provide our customers with the best value for their investment.

7. FAQ

(1) Q: How do I know which size of cartridge heater to choose for my injection mold?

A: You need to consider the size of the mold cavity, the required heating power, and the available space for installation. Our technical team can also assist you in selecting the right size based on your mold specifications.

(2) Q: Are your cartridge heaters compatible with all types of injection molds?

A: Our cartridge heaters are designed to be compatible with most common injection molds. However, if you have a specialized or unique mold design, please contact us to discuss compatibility.

(3) Q: How do I select the right 220V cartridge heater for my injection molding process?

A: Choosing the right cartridge heater involves considering factors such as the required heating capacity, desired operating temperature range, mold size, material compatibility, and any specific application requirements. Consulting with the manufacturer or a heating system expert can help ensure the optimal selection.

8. Summarize

Our customized cartridge heaters are manufactured with the highest standards of quality and precision. As a trusted manufacturer based in China, we have the expertise and experience to tailor our cartridge heaters to meet your specific requirements. Whether you need a specific power rating, voltage, diameter, length, or have unique application needs, we can accommodate your customization requests.

Hope we can have a chance to be your reliable supplier.